The Basics of Air Hoses: Materials, Sizes, Lengths, Fittings, and Maintenance

Air hoses are an essential part of many industries, providing a means of transmitting compressed air from a compressor to a pneumatic tool or piece of equipment. These hoses come in a variety of materials, sizes, and lengths, each with its own advantages and disadvantages.

Materials

Air hoses can be made from a range of materials, including rubber, PVC, polyurethane, and nylon. Rubber air hoses are the most common, and they are often reinforced with braided fibers for added strength. PVC air hoses are lightweight and flexible, making them easy to maneuver, but they are not as durable as rubber hoses. Polyurethane hoses are also lightweight and flexible, and they are more resistant to kinks and abrasions than PVC hoses. Nylon hoses are the most durable of the four, but they are also the least flexible.

High Pressure Air Hose

Sizes

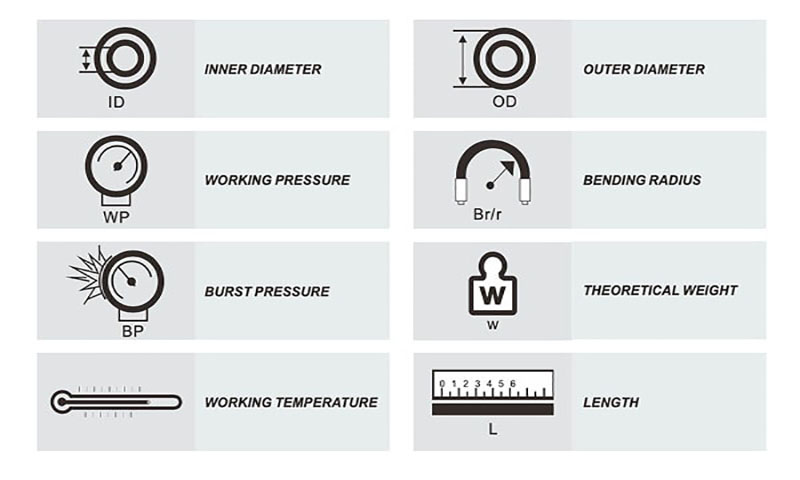

Air hoses come in a range of sizes, which are typically measured by their inside diameter (ID). Common sizes include 1/4″, 3/8″, and 1/2″. The size of the hose you need will depend on the amount of air your tool or equipment requires, as well as the length of the hose and the pressure of your compressor.

Lengths

Air hoses can be purchased in a variety of lengths, ranging from a few feet to several hundred feet. The length you need will depend on the distance between your compressor and the tool or equipment you are using. It’s important to choose a hose that is long enough to reach your equipment without being stretched or pulled taut, as this can cause the hose to become kinked or damaged.

Hose diameter and length

Fittings

Air hoses typically come with fittings already attached, but it’s important to ensure that the fittings are compatible with your compressor and tool or equipment. Common fittings include quick-connect couplers, which allow you to quickly and easily connect and disconnect the hose, and threaded fittings, which are more secure but require more time to attach and detach.

rubber air hose with fittings

Maintenance

Proper maintenance of your air hose is essential for its longevity and safety. Always inspect your hose for damage before use, and replace any hoses that are cracked, frayed, or damaged. Store your hose in a cool, dry place when not in use, and avoid exposing it to direct sunlight or extreme temperatures. Always use the appropriate type and size of hose for your tool or equipment, and be sure to follow the manufacturer’s instructions for use.

sunhose

sunhose sunhose

sunhose