A compressor air hose is an essential tool for anyone working with pneumatic tools or machinery. It is a flexible, reinforced hose that connects the air compressor to pneumatic tools, such as nail guns, impact wrenches, sanders, and grinders. The hose transports compressed air from the compressor to the tool, enabling it to function correctly. In this article, we will discuss the various aspects of compressor air hoses, including their types, uses, benefits, and maintenance.

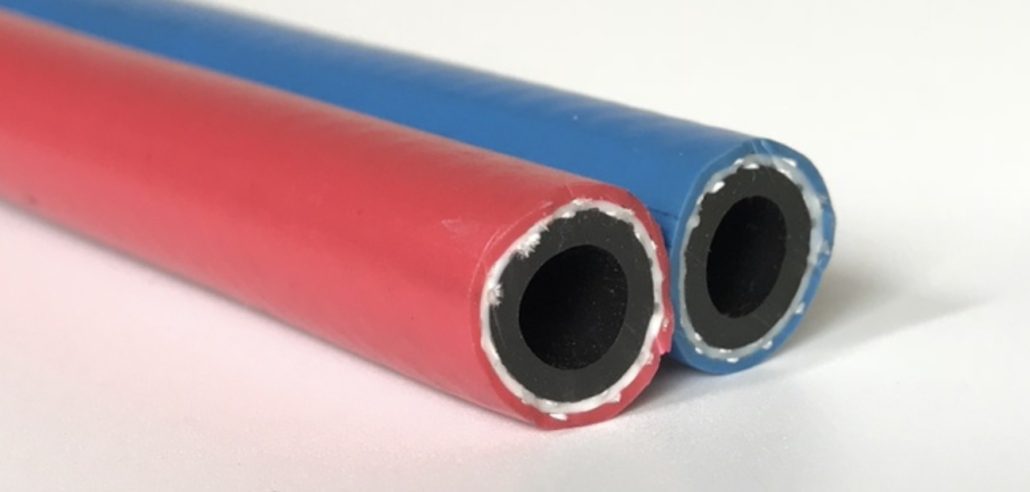

compressor air hoses

Types of Compressor Air Hoses:

There are several types of compressor air hoses available in the market, each with its specific features and benefits. Let’s take a look at some of the most popular types:

red air hose

- PVC Air Hose: PVC air hoses are lightweight, flexible, and easy to handle. They are the most commonly used type of air hose, especially for low-pressure applications. However, PVC hoses are not suitable for high-pressure applications or extreme temperatures.

- Rubber Air Hose: Rubber air hoses are heavy-duty and can handle high-pressure applications and extreme temperatures. They are more durable than PVC hoses and can last longer. However, rubber hoses are more expensive than PVC hoses and can be less flexible.

- Hybrid Air Hose: Hybrid air hoses combine the benefits of PVC and rubber hoses. They are lightweight, flexible, and easy to handle, like PVC hoses, and can handle high-pressure applications and extreme temperatures, like rubber hoses.

- Polyurethane Air Hose: Polyurethane air hoses are lightweight, flexible, and highly durable. They are resistant to kinks and abrasions, making them ideal for heavy-duty applications. However, polyurethane hoses are more expensive than other types of hoses.

Uses of Compressor Air Hoses:

Compressor air hoses are used in a wide range of applications, including:

- Construction: Compressor air hoses are used in construction sites to power pneumatic tools, such as nail guns, jackhammers, and impact wrenches.

- Automotive: Compressor air hoses are used in automotive workshops to power air tools, such as air ratchets, impact wrenches, and spray guns.

- Manufacturing: Compressor air hoses are used in manufacturing plants to power pneumatic tools, such as sanders, grinders, and drills.

- DIY Projects: Compressor air hoses are also used in DIY projects, such as painting, sanding, and inflating tires.

Benefits of Compressor Air Hoses:

- Increased Efficiency: Compressor air hoses increase the efficiency of pneumatic tools by providing a steady flow of compressed air. This allows the tools to operate at their optimal level and complete tasks more quickly.

- Versatility: Compressor air hoses can be used with a wide range of pneumatic tools, making them highly versatile.

- Durability: High-quality compressor air hoses are highly durable and can withstand heavy-duty applications.

- Safety: Compressor air hoses are designed to handle high pressures, making them safe to use with pneumatic tools.

- Portability: Compressor air hoses are lightweight and easy to carry, making them ideal for on-the-go applications.

Maintenance of Compressor Air Hoses:

To ensure the longevity and efficiency of compressor air hoses, proper maintenance is essential. Here are some tips for maintaining your compressor air hose:

- Inspect the hose regularly for signs of wear and tear, such as cracks, kinks, or leaks.

- Store the hose properly when not in use, coiling it neatly and securing it with clips or ties.

- Clean the hose regularly using mild detergent and water to remove dirt, oil, and debris.

- Avoid exposing the hose to extreme temperatures, direct sunlight, or chemicals

- Use the appropriate type of hose for the application. For example, use a rubber hose for high-pressure applications and extreme temperatures, and a PVC hose for low-pressure applications.

- Use a hose reel to store the hose, which helps to keep it organized and prevents kinks and tangles.

- Check the fittings and connectors regularly, ensuring that they are tight and secure.

- Replace the hose when it shows signs of wear and tear, or if it fails to function correctly.

blue air hose

In conclusion, a compressor air hose is a vital tool for anyone working with pneumatic tools or machinery. It enables the smooth and efficient functioning of the tools and increases productivity. Compressor air hoses come in various types, each with its unique features and benefits, making them highly versatile. They are used in a wide range of applications, including construction, automotive, manufacturing, and DIY projects. Proper maintenance is essential to ensure the longevity and efficiency of compressor air hoses. By following the tips mentioned above, you can keep your compressor air hose in excellent condition and extend its lifespan.

sunhose

sunhose