PVC vs Rubber Air Hose

An Air hose is a hose for conducting air under pressure, as one connected to an air pump, an air brake, or a scuba tank. Such as an air tool or air compressor. An air hose could be made of many particles as much as there are so many kinds of air hoses. The most common ones on the market are PVC air hoses and rubber air hoses. Also, Polyurethane Air Hose is very expensive.

When it comes to selecting an air hose for various applications, two popular options emerge: PVC (Polyvinyl Chloride) and rubber. Both materials have unique characteristics that make them suitable for different scenarios. In this article, we delve into the comparison between PVC and rubber air hoses, exploring their properties, advantages, disadvantages, and typical applications. By understanding the differences between these two materials, you can make an informed decision and select the most suitable air hose for your specific needs.

- ITEM

- Material

- Flexibility

- Wight

- Durability

- Usage

- Price

- PVC AIR HOSE

- SG-5 PVC Material

- Will be stiff in Winter

- Lightweight

- Color change after a long time

- Good for its resistance

- Cheaper

- RUBBER AIR HOSE

- Flexible rubber NBR

- More flexible at any temperature

- More Heavy than PVC

- Prone to aging and cracking

- Good for its resiliency

- Expensive

PVC AIR HOSE

RUBBER AIR HOSE

PVC Air Hose

PVC meaning is Polyvinyl chloride. It is a synthetic resin made from the polymerization of vinyl chloride. PVC’s second immense use is polythene. PVC use for making polythene in a huge rush.PVC hose is very stable and friction-resistant. Though it is not as flexible as other variations, it is so helpful in the winter season, and other times it works so little. It is also easy to get around corners and barriers without getting any hung up.

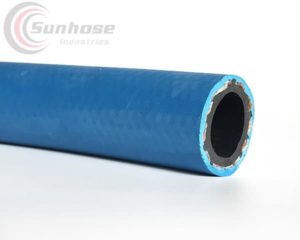

Rubber Air Hose

The nitrile rubber and polyurethane are the primary particles of rubber air hose. The rubber air hose’s range of working pressures is from 150 to 300 PSI. There are various sizes and colors available for rubber air hoses. You can choose your favorite one. Using the rubber air hoses in mining, drilling, and construction could degrade the rubber air hose. So users should understand where they should use that, and they have to maintain the life expectancy, the frequency of use, and the type of elements the hose will be subject to.

sunhose

sunhose Sunhose

Sunhose