What are the manufacturing processes of PVC hose pipe?

manufacturing processes standard specifications testing requirements packaging shipping. The technology of PVC pipe manufacturing processes is extensive and involved. Well before a finished PVC product is ready for testing, inspection, and delivery, its beginnings can be traced from oil or gas wells, through petrochemical plants to PVC compounding operations, and finally to automated extrusion, molding, and fabrication operations.

PVC pipe is produced from a blend of materials whose major ingredient is polyvinyl chloride resin. In the plastics industry, the word “resin” refers to the basic polymer used as raw material and “compound” refers to a homogeneous blend of resin and various additives. Polyvinyl chloride resin is a thermoplastic polymer produced by the polymerization of vinyl chloride monomer (VCM). Vinyl chloride is a colorless gas produced from chlorine and ethylene. In North America, the raw materials of vinyl chloride monomer are saltwater and natural gas. The terms thermoplasticity, polymer, monomer, and polymerization are defined as follows: Thermoplasticity refers to the property that enables a material to be repeatedly softened by an increase in temperature and hardened by a decrease in temperature. A polymer is an organic material that contains a large number of the same chemical configurations, attached to each other like links in a chain. The long chains result in high molecular weight. A monomer is the simple, small molecule from which the polymer chain is made. Polymerization is the reaction that bonds monomers into the large structure of the polymer. Polymers are not exclusively manmade; they are also found in a large variety of natural materials such as protein, cellulose, starch, and rubbers. There are many polymerization processes that convert vinyl chloride monomer into polyvinyl chloride resin (polymer). Two processes are best suited to the manufacture of the type of high-quality PVC resin needed for pipe. They are (1) suspension polymerization and (2) mass (sometimes termed “bulk”) polymerization. These are economical processes used in the production of virtually all PVC pipe-grade resins today.

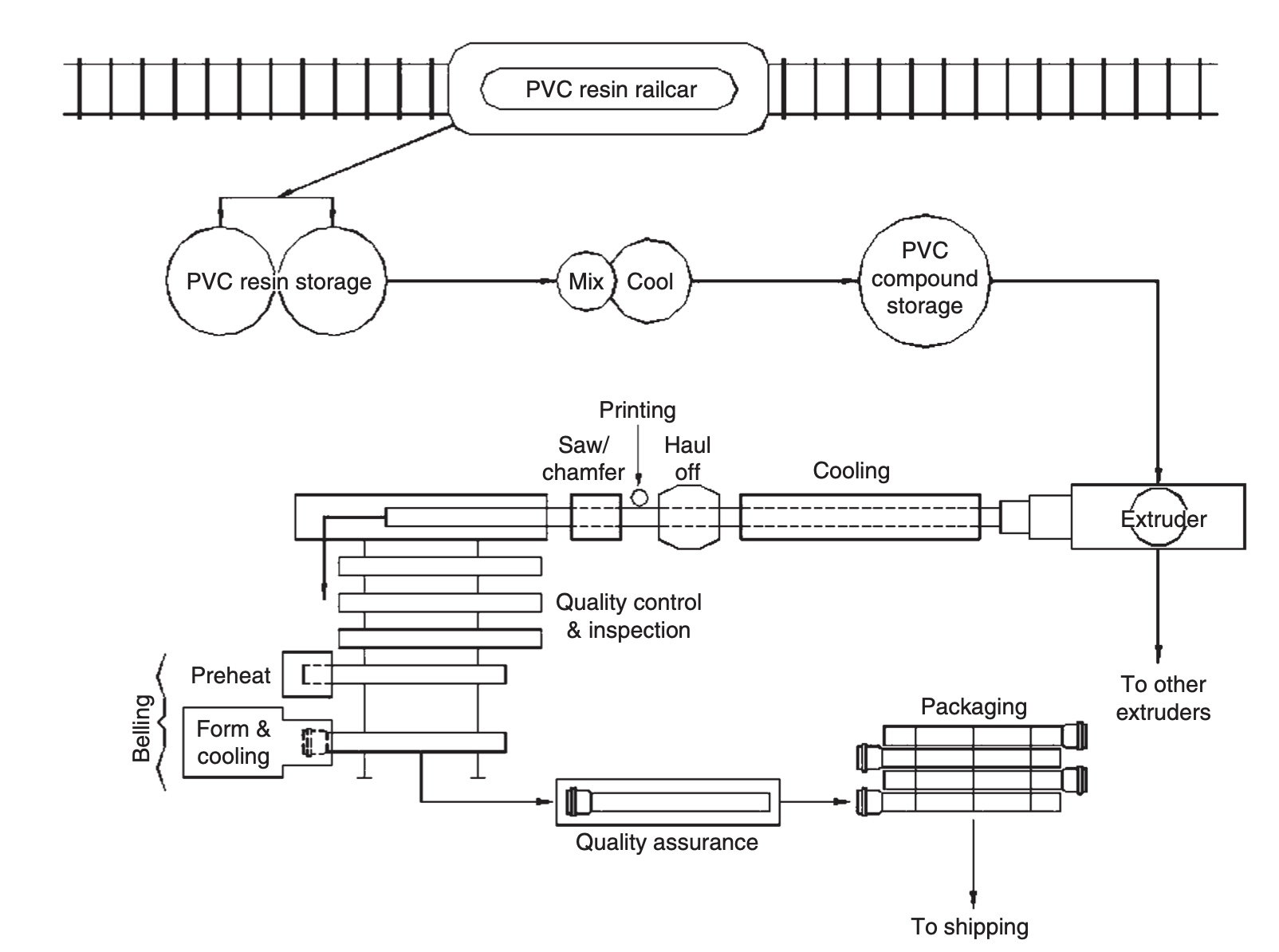

After production and quality assurance, resin manufacturers ship the PVC resin (in powder form) to pipe producers. Product parameters commonly evaluated include molecular weight, particle size/dimension, volatiles content, bulk density, flow time, and residual VCM. Large 200,000-lb bulk railcars or 40,000-lb bulk trucks are normally used to transport the PVC resin. Upon arrival at a pipe manufacturer, the resin is pneumatically conveyed from the bulk transporters into the pipe production plant and stored in silos.

Other ingredients that are compounded with the PVC resin include stabilizers, pigments, lubricants, processing aids, and functional additives. Each ingredient is used to impart specific processing characteristics or to enhance specific finished product properties. For instance, functional additives may be used to increase the PVC compound’s modulus of elasticity. The proportions of these minor ingredients will vary from compound to compound. The formulations, which stipulate the percentages and actual ingredients used in a given PVC pipe compound, are developed to impart specific properties dictated by the application.

The process used to mix PVC resin with minor ingredients to produce PVC pipe extrusion compound is termed dry-blend compounding or dry blending. Dry blending is performed in a high-speed, intensive mixer. In the process, the friction created by high-speed rotation of the mixer blades and intense movement of material particles generates substantial heat, elevating the temperature of the blending materials. As PVC particles are heated they expand, developing a porous, irregular appearance similar to that of popcorn. These particles then become uniformly coated with minor ingredients in proportions determined by the compound formulation (some ingredients, such as lubricants, melt at elevated temperatures, permitting thorough dispersion and providing added homogeneity to the blend). After intensive mixing at elevated temperatures for several minutes, the preparation of a PVC compound batch is complete. The batch is then cooled and transported to compound silos for storage and later use. Upon demand, the extrusion compound is pneumatically conveyed to the pipe extrusion operation, where it is fed into hoppers. The compound is then metered into the extruders and pipe production commences.

Manufacturing of Solid-Wall Pipe

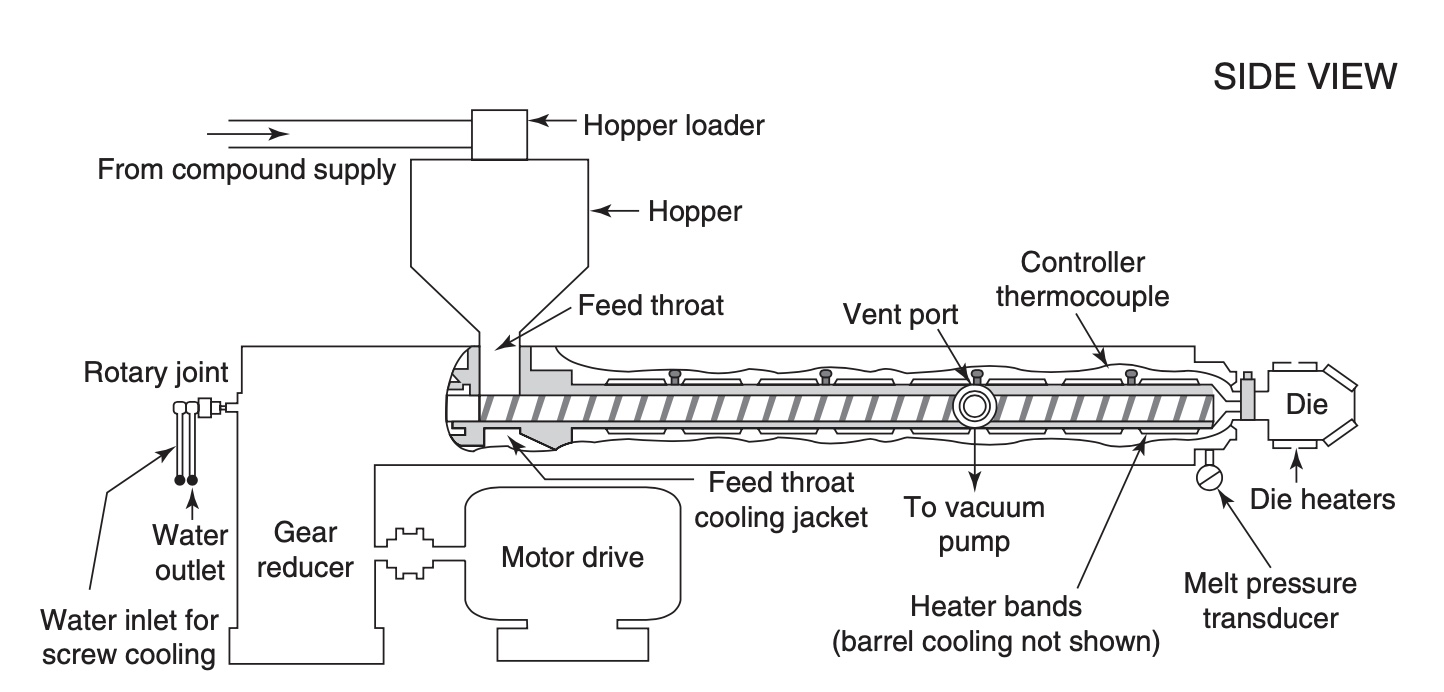

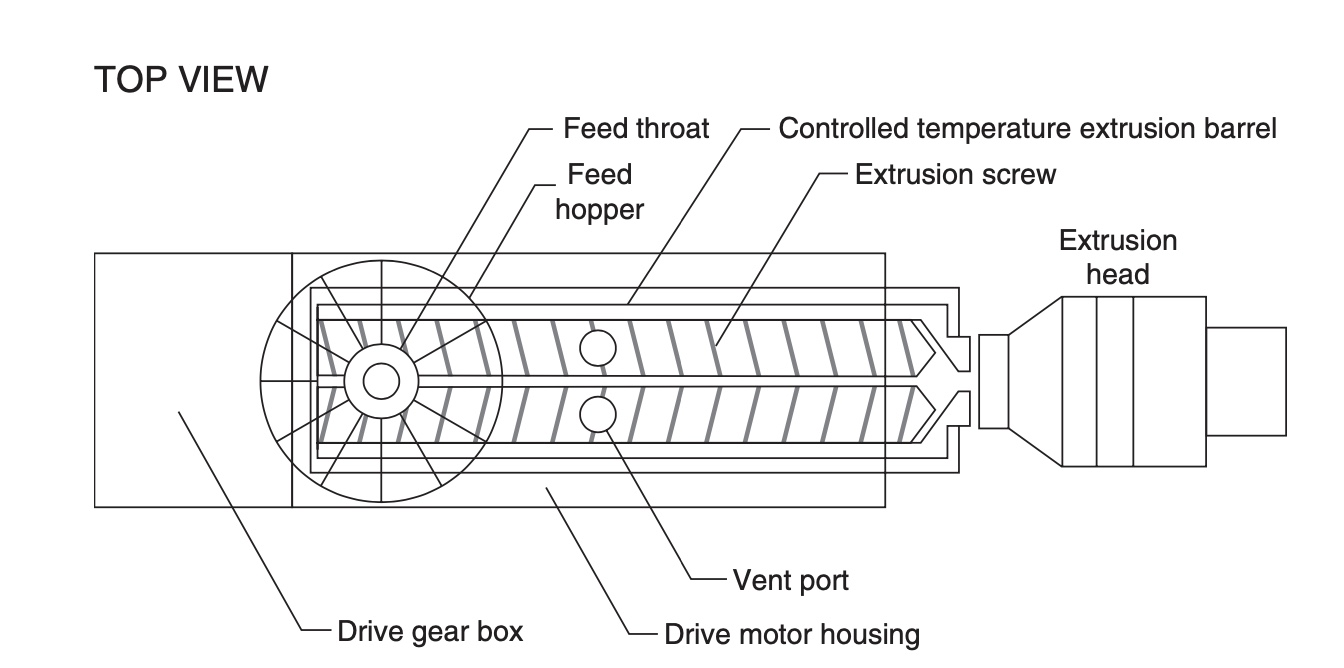

PVC solid-wall pipe takes the form of a cylinder with homogeneous walls of uniform thickness. Both the interior and exterior surfaces are smooth. Solid-wall manufacturing processes allow pipes to be produced in sizes from tiny 1/8-in. Schedule 40 tubing up to massive 60-in. municipal pressure pipe. Almost all extruded plastic products are produced on two classes of extruders: (1) single-screw extruders (Fig. 1) or (2) multi-screw extruders (Fig. 2). Products made on single-screw extruders include garden hoses, fishing line filaments, and artificial wood molding. Also, most pipes are made from thermoplastic materials other than PVC, such as styrene, polybutylene (PB), polyethylene (PE), and acrylonitrile butadiene styrene (ABS), are produced on single-screw extruders. Although single-screw machines can be used for PVC pipe, the bulk of PVC pipe produced in the world today is manufactured on multi- screw extruders.

Fig. 1

Fig. 2

The popularity of the multi-screw extruder for the production of PVC pipe can be attributed to the additional processing flexibility it offers over single-screw extruders. The same toughness and strength that makes PVC such an excellent pipe material also renders it a relatively difficult material to process. The multi-screw extruder’s versatility allows processing at lower temperatures for excellent dimensional control, with smaller quantities of necessary compounding ingredients, providing PVC its full potential strength. PVC compound in its powder form flows from the feed hopper through the feed throat into the extruder barrel, where it is received by rotating screws. The material is then conveyed with a pumping action by the intermeshing screw flights through the extruder. As the material passes through the extruder and is exposed to carefully controlled heat and pressure, it is converted from the dry powder into a viscous plastic mass. This process is carefully monitored and accurately controlled in order to guarantee the correct properties in the finished product. When the plasticating (softening) process is complete and volatiles have been removed from the molten plastic, the material is properly prepared for final forming. The viscous, elastic mass of plastic is extruded into the pipe-forming die under high pressure (2,000–5,000 psi). In the pipe, extrusion dies the hot plastic material is formed into a cylindrical shape. As it leaves the extrusion die at the exit orifice, the material is extremely hot (about 400°F), flexible, and pliable. In this state, the hot plastic is formed with dimensional accuracy into a finished product and then cooled into a solid state. Outside diameter dimensional control is established by forcing the hot plastic through a sizing sleeve with a piece of equipment commonly called a haul-off, as it is drawn away from the extruder. Wall thickness control is established through proper synchronization of haul-off and extruder speeds.

Wall thickness is normally adjusted by varying the speed of the haul-off. Reduction of haul-off speed increases wall thickness, while the increase in haul-off speed reduces wall thickness. When substantial changes in wall thickness are required, so too are changes in extrusion tooling dimensions. Upon completion of final forming, the extruded PVC pipe is drawn away from the extruder into cooling tanks, where it is cooled by chilled water. By the time the pipe emerges from the end of the cooling tanks, it has cooled to a temperature at which it can be handled without distortion. After leaving the cooling station, the pipe travels through a printing station, where pertinent product and process information is printed on the pipe. Beyond the printer, the pipe is automatically cut to a correct length with chamfered ends, a process accomplished with a planetary saw that cuts and chamfers as it travels with the moving pipe. (See Fig. 3 for a flow chart of the manufacturing process.)

Fig. 3

sunhose

sunhose sunhose

sunhose